Bar Tips

Product Highlights

- 3/8″ Standard

- 3/8″ Narrow

- 3/8″ Wide (3 rivet German)

- .404″ Standard

- .404″ Wide (3 rivet German)

- .404″-.080 internal

- .325″ Standard

- 3/4″ Standard

Cannon Bars Works sells all of our standard tip models to support the full line of bars that we make.

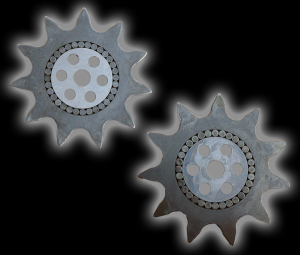

Harvester Sprockets

Product Highlights

Our .404” pitch and ¾” pitch harvester sprockets are made to our own specifications and feature very high quality bearings and the side plates are made from an extremely hard and wear resistant steel alloy. They can also be used as replacement sprocket noses for both Oregon and Gem Harvester bars.

The cost of both of the sprocket noses is very reasonable compared to the competition as well. We repair a large number of harvester bars and almost always the customers want us to use the Cannon sprocket noses on the harvester bars when we repair them.

Roller Nose for Competition Bars

Product Highlights

The roller nose is a re-creation of the original roller noses that were popular in the 1950’s. We redesigned them for competition bars with the feature that the can be operated at up 25,000 RPM! Speed is the name of the game when you are chainsaw racing.

It should be kept in mind that they are not designed for bore cutting or typical chainsaw cutting; they are sort of like a very high end race car which you would not refer to as “Street Legal”.

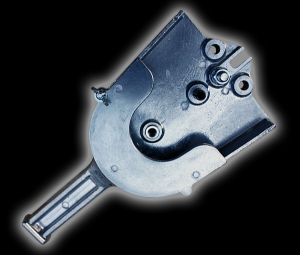

Cannon Adaptor Plates

Product Highlights

Cut from the same durable steel that SuperBars are made from

Cannon offers many different adaptor plate options to allow users to convert a Stihl® mount bar (12mm bar stud), or the Cannon G1 mount bar for use on other makes and models of chainsaws. For a full list of the adaptor plates please see the link below.

This is an economical way to use one bar on two different saws. For whatever reason this situation may occur, these handy adapter plates

will help you get the job done.

As you can see, the adaptor fits snugly in the bar slot, and the plate screw secures it to the saw.

Helper Handle (Milling Bars)

Product Highlights

The helper handles are made and designed by the good folks at Granberg.

There are two types, the HH-975 is designed for use with double-ended chainsaw milling bars, “Cannon SawMiller” and includes a roller assembly and a chain tensioning device. The oiler kit is also from Granberg and we highly recommend using them when you are slab cutting with a chainsaw mill; there is no such thing as too much bar and chain oil especially when using long bars.

The HH-971 is used with long SuperBars. The long bars are quite heavy and when making six, seven and eight foot cuts it really helps to have someone using the helper handle on the far end of the bar. Using the helper handle will allow you to keep the bar straight when making big bucking cuts. We have a special template to drill a couple of holes in the sprocket so that the helper handle can be installed correctly.

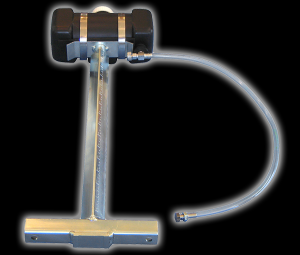

Granberg Oiler Kit

Product Highlights

Designed to mount with double end saw bars larger than 36″.

Oil is injected in to the groove at the working end of the saw bar. Flow is controlled by a valve on the tank and oil is delivered by gravity. The Auxiliary Oiler Kit will extend saw bar life, provides for cooler cutting and prevents early bar wear.

For non double end bars, two holes must be drilled in saw bar tip.

Newer saws with better oiling systems may not require additional lubrication.